Introduction to stainless steel wire drawing process

The wire drawing process is a metal processing process. in metal press working. Under the action of external force, the metal is forced through the die, the metal cross-sectional area is compressed, and the technical processing method of obtaining the required shape and size of the cross-sectional area is called metal drawing process. make it change shape. The sized tool is called a wire drawing die. For example, in the cable industry, the 8mm copper rod is drawn into a copper wire, such as 3.5mm, 2.0mm, etc., through a set of (5~8) drawing dies from large to small.

Machining surface treatment: Wire drawing is a method in which the reciprocating motion of the wire drawing cloth is used to rub back and forth on the surface of the workpiece to improve the surface finish of the workpiece, and the surface texture is linear. It can improve the surface quality and hide minor scratches on the surface.

Characteristics of wire drawing process

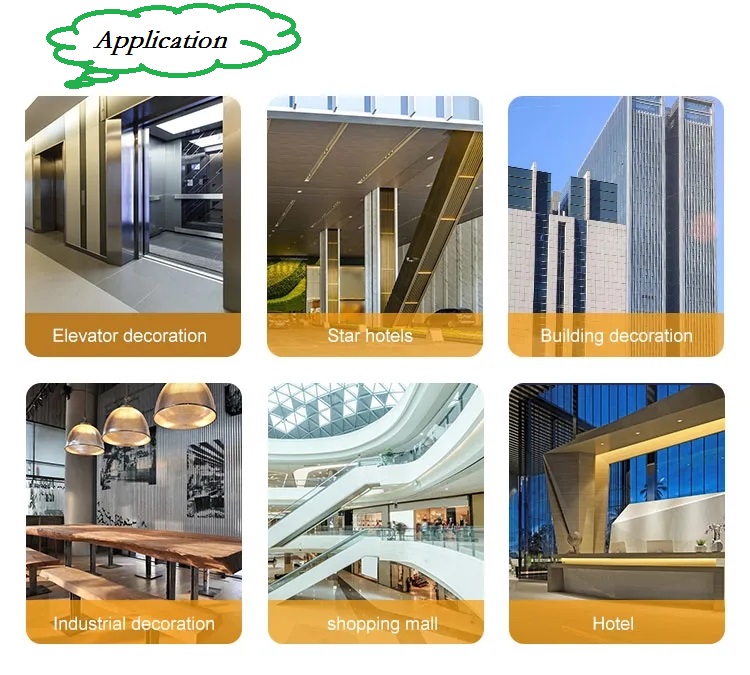

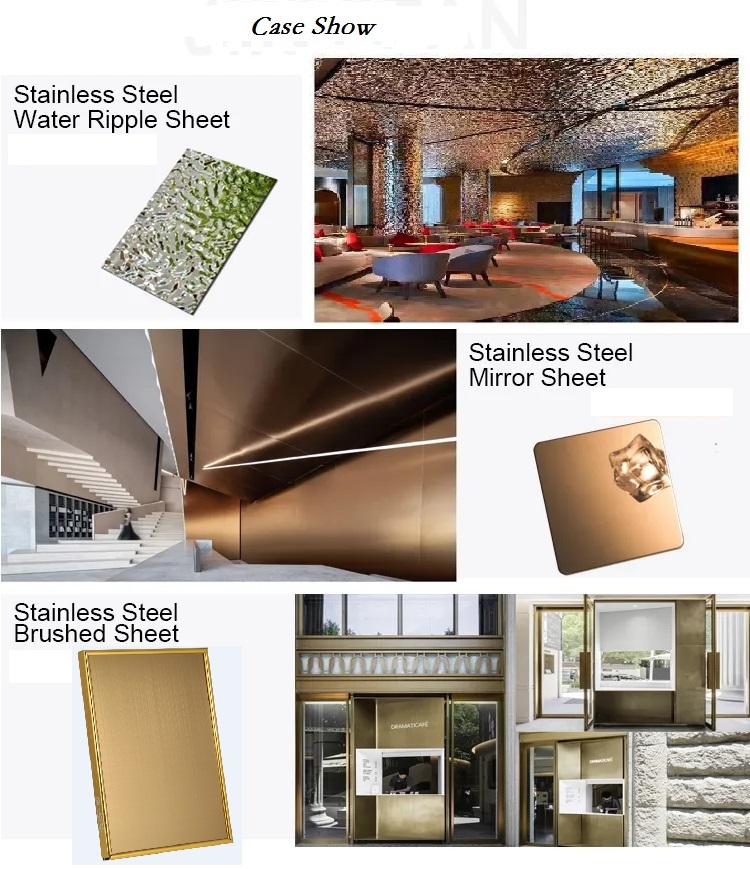

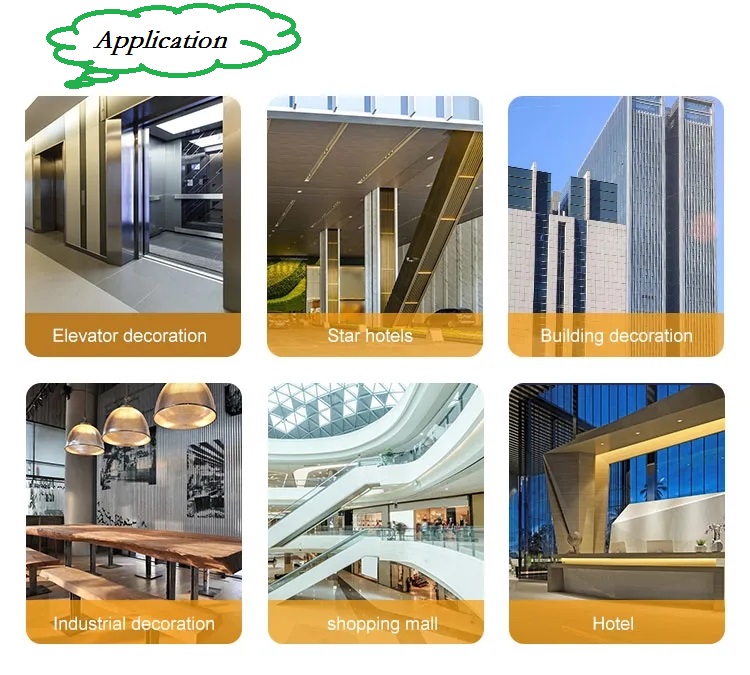

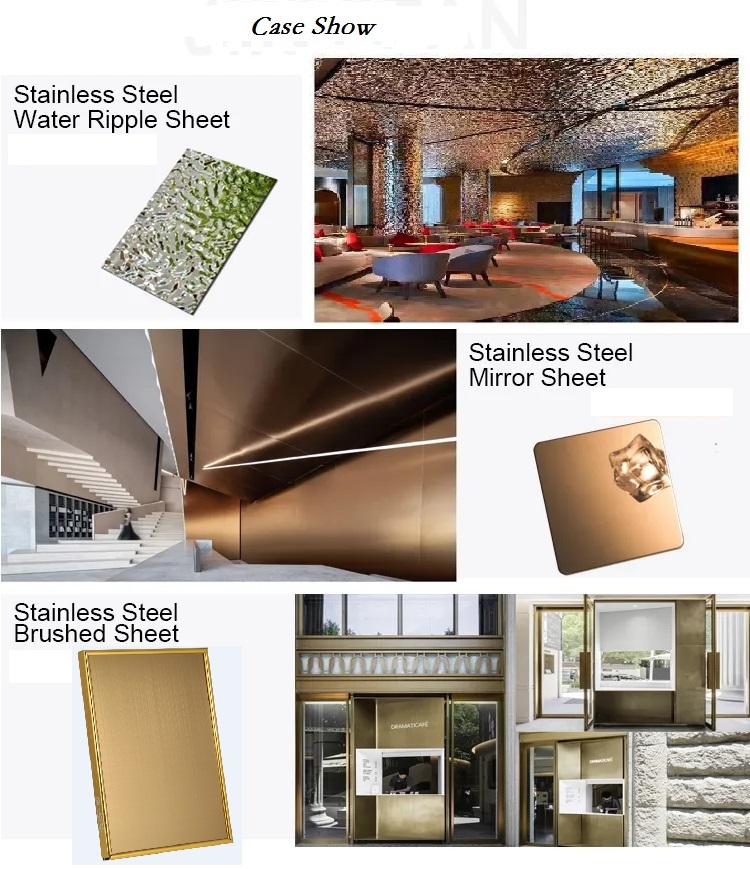

In order to break through the designer's restrictions on the use of decorative materials and meet more creative needs, in the new century, human beings affirm themselves and explore the unknown, and develop and design gold and silver wire drawing that combines knowledge and technology spirit. Veneer sheet metal. Such products include gold wire drawing, silver wire drawing, snowflake sand, and sandblasting surface, which can fully reflect the heavy metal feeling that is difficult to express in other plates such as gold and silver. Gold and silver are rich and noble colors and are symbols of status and status. The main metal materials used in gold and silver brushed veneer metal plates can be divided into three categories: aluminum, copper and stainless steel. With the texture, luster and characteristics of the original metal form, matte, mirror, three-dimensional, embossed and special Various surface treatments such as veneer and metal strands. According to the designer, it shows a resplendent effect on different occasions.

The role of the wire drawing process

The surface of the metal plate has the characteristics of anti-rust, anti-oxidation, anti-scratch, anti-chemical agent and anti-smoking. In appearance, due to the special bright surface of the product itself, in order to avoid tarnishing due to friction, it is recommended to use it on a horizontal surface with less friction, or a general vertical surface. In addition, this product is recommended to be used in a dry place, or in a place where it will not be wet and the moisture will not be too heavy to maintain the stability of the product. The wire drawing of the metal surface can well cover the mechanical lines and mold clamping defects in the production.

What is the difference between the wire drawing process and the polishing process

Wire drawing is a method of using the reciprocating motion of the wire drawing cloth to rub back and forth on the surface of the workpiece to improve the surface finish of the workpiece, and the surface texture is linear.