According to the definition in GB/T20878-2007, stainless steel is a steel whose main characteristics are stainless and corrosion resistance, with a chromium content of at least 10.5% and a maximum carbon content of no more than 1.2%.

Stainless steel is the abbreviation of stainless acid-resistant steel. The steel grades that are resistant to weak corrosive media such as air, steam, and water, or have stainless properties are called stainless steel; Corrosion) Corroded steel is called acid-resistant steel.

The corrosion resistance of stainless steel decreases with the increase of carbon content. Therefore, the carbon content of most stainless steels is low, the maximum does not exceed 1.2%, and the ωc (carbon content) of some steels is even lower than 0.03% (such as 00Cr12 ). The main alloying element in stainless steel is Cr (chromium). Only when the Cr content reaches a certain value, the steel has corrosion resistance. Therefore, stainless steel generally has a Cr (chromium) content of at least 10.5%. Stainless steel also contains Ni, Ti, Mn, N, Nb, Mo, Si, Cu and other elements.

Generally speaking, the hardness of stainless steel is higher than that of aluminum alloy, and the cost of stainless steel is higher than that of aluminum alloy.

1. Stainless steel crude steel smelting process

At present, the smelting process for producing stainless steel in the world is mainly divided into one-step method, two-step method and three-step method, as well as a new integrated production method. The one-step smelting method is: molten iron + AOD; the two-step method is: EAF + AOD. The three-step method is: EAF + AOD + VOD. In addition to several traditional production processes, the current integrated production process, that is, the production process from molten iron directly to stainless steel, is also adopted by many companies. The production process is: RKEF + AOD.

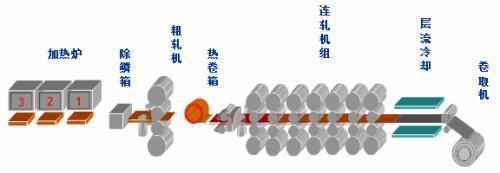

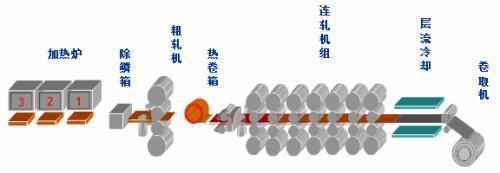

2. Stainless steel hot rolling process

The stainless steel hot rolling process uses slabs (mainly continuous casting slabs) as raw materials, and after heating, they are made into strip steel by rough rolling units and finishing rolling units. The hot steel strip coming out of the last rolling mill of finishing rolling is cooled to the set temperature by laminar flow, and rolled into steel coil by the coiler. After cooling, the steel coil has scale on the surface and appears black, commonly known as "stainless steel black coil". . After annealing and pickling, the oxidized surface is removed, which is "stainless steel white coil". Most of the hot-rolled products circulating in the stainless steel market are stainless steel white coils. The specific stainless steel hot rolling production process is as follows:

3. Stainless steel cold rolling process

After stainless steel hot rolling, some stainless steel hot rolled products are directly used downstream, and some hot rolled products need to be processed into cold rolling before use.

Stainless steel cold-rolled products are mostly hot-rolled stainless steel products with a thickness of 3.0-5.5mm, which are produced into stainless steel cold-rolled products after being calendered by cold-rolling equipment. There are currently two main production processes for stainless steel cold rolling: stainless steel single-stand cold rolling and stainless steel multi-stand cold rolling. The specific production process is as follows:

After the stainless steel is cold rolled, it needs to go through an annealing and pickling unit. The annealing of stainless steel after cold rolling is to eliminate work hardening through the process of recrystallization to achieve the purpose of softening; the purpose of pickling is to remove the oxide layer formed on the surface of the steel strip during the annealing process, and the second is to passivate the surface of the stainless steel , Improve the corrosion resistance of the steel plate.