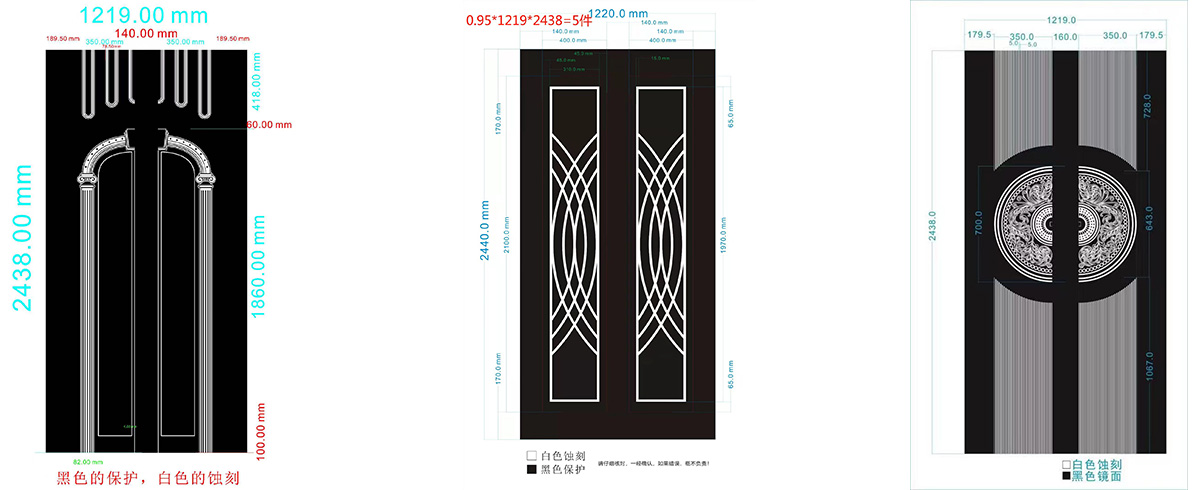

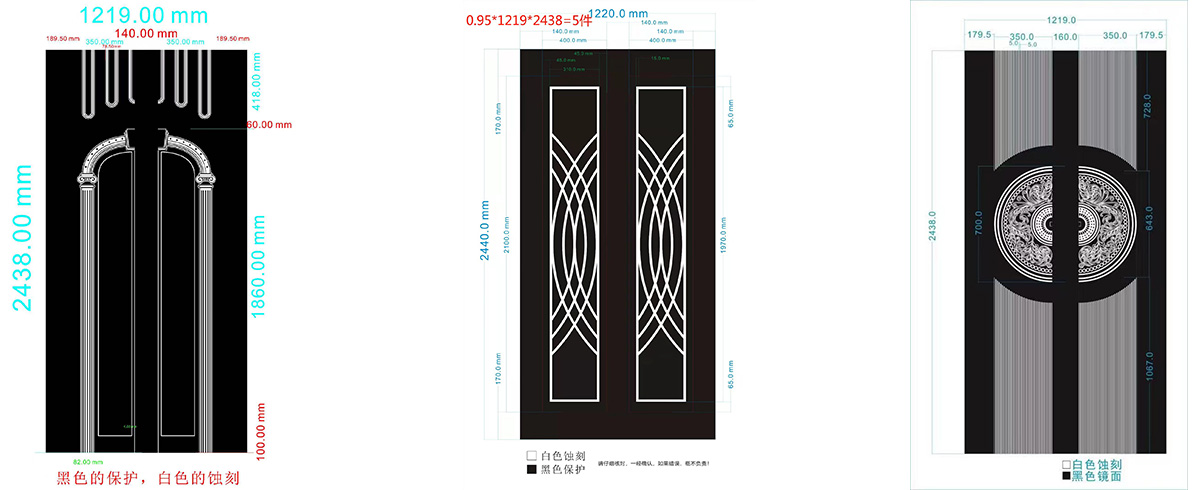

China etching stainless steel sheet 1.2 mm Thick for elevator door

The process principle of chemically etching patterns and texts on the surface of stainless steel is to use a special anti-corrosion layer to cover the surface of the part that will not be etched by chemical methods on the surface of stainless steel, and etch out various patterns. With 8K mirror panel, brushed board, and sandblasting board as the base plate, after etching treatment, the surface of the object is further processed. The stainless steel etching plate can be processed with various complex processes such as partial texture, brushed, gold inlay, and partial titanium gold. , Stainless steel etched plate to achieve the effect of light and dark patterns and brilliant colors.

The general process is as follows: degreasing → cleaning → drying → silk screen → drying → water immersion → etching leaf (piece) cleaning → signature → cleaning → polishing → cleaning → coloring → washing leaf (piece) hardening treatment → sealing treatment → cleaning leaf (piece) →Drying→Check the product.

Can be customized according to the pattern design