304 316 #4 Brush Finish Stainless Steel Coil With Mill Test

Description

No.4, also called #4, satin or directional finish, is an unidirectional finish obtained with a 100-400 grit abrasive depending on requirements. High grit numbers create finer polishing lines and more reflective finishes.

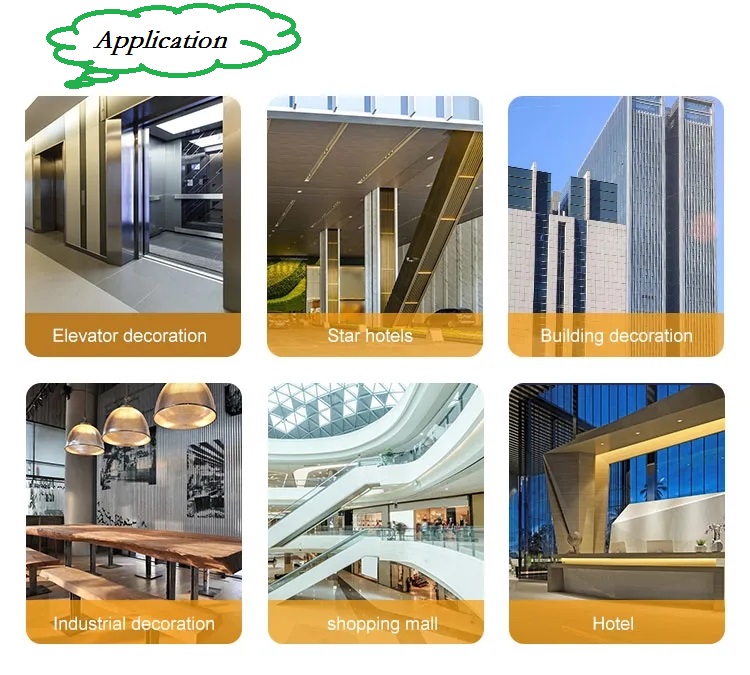

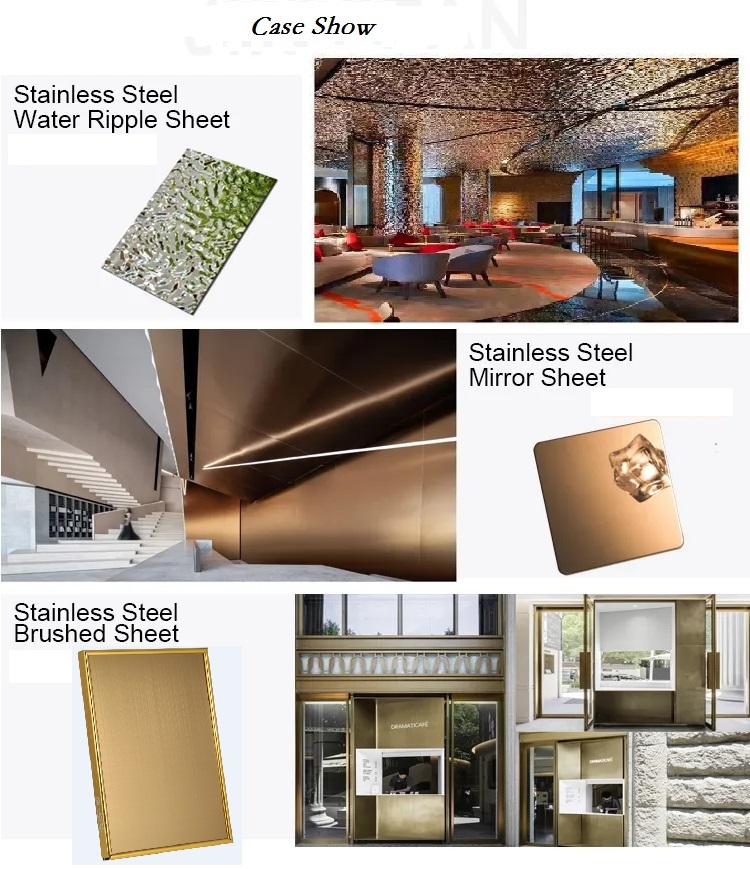

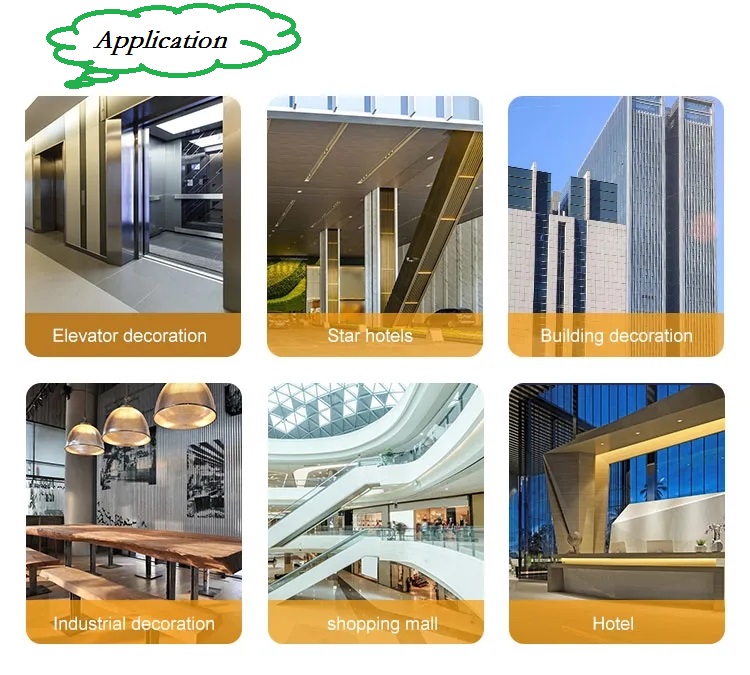

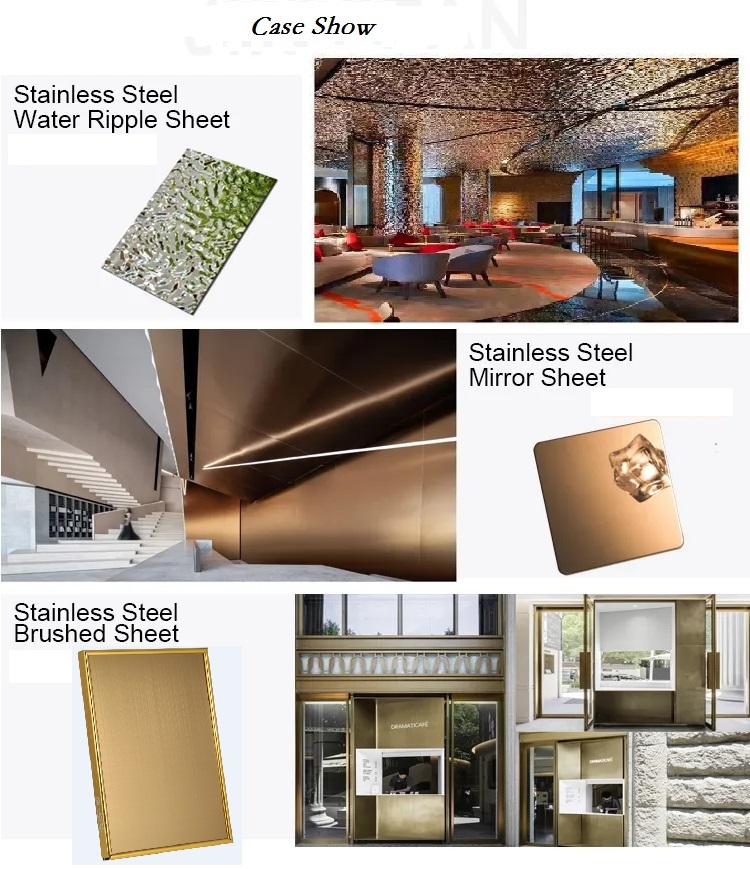

Application Field

No.4, Be extensively applied to architectural decoration, such as elevator decoration, luxurious doors, outdoor projects, wall decoration, advertisement nameplates, sanitary ware, ceiling, corridor, hotel hall, shop facade, etc.

For furniture, kitchenware, food industry, electronic industry, medical equipment, etc.

Structure of Stainless Steel Coil Cold Rolled 201 Descriptions

Stainless Steel 201 is a new kind of Austenite stainless steel by used Mn, N replace Ni. The steel has good corrosion resistance and hot / cold processing performance, instead of 304 stainless steel products for used in the not high of corrosive environment, such as indoor, inland city outdoor etc.

Surface of stainless steel coils

No.1 | The surface is finished by heat treatment and pickling or processes corresponding there to after hot rolling |

2D | The finishes after cold rolling, by heat treatment, pickling or other equivalent treatment |

2B | The finish after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to give an appropriate luster |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror |

NO.3 | Polished with abrasive belt of grit#100~#200,have better brightness with discontinuous coarse stria |

NO.4 | Polished with abrasive belt of grit#150~#180,have better brightness with discontinuous coarse stria |

HL | Polished with abrasive belt of grit#150~#320 on the NO.4 finish and has continuous streaks |

8K | The product have excellent brightness and prefect reflexivity can be the mirror.

|